Planning Your DIY Built-In Cabinet Project

Building custom cabinets is a rewarding way to enhance your home’s functionality and aesthetics. However, it requires careful planning and preparation to ensure a successful outcome.

Planning Your Project

Before diving into construction, carefully plan your project. This involves considering your space, design preferences, and budget.

- Define Your Needs: Identify the purpose of the cabinets. Are they for storage, display, or both? What items will be stored in them? This helps determine the size, configuration, and features required.

- Measure Your Space: Accurately measure the available space, taking into account any existing features like walls, windows, or doors. Consider the depth, width, and height of the cabinets to ensure they fit comfortably and provide adequate storage.

- Sketch Your Design: Create a simple sketch or diagram of the cabinet layout. Include the number of cabinets, their dimensions, and any desired features like shelves, drawers, or doors. This visual representation helps you visualize the final result and identify potential challenges.

Determining Cabinet Dimensions and Configuration

The optimal cabinet dimensions and configuration depend on the available space and your storage needs.

- Standard Cabinet Depths: Common cabinet depths range from 12 inches to 24 inches. Consider the size of the items you plan to store to choose an appropriate depth.

- Standard Cabinet Heights: Typical cabinet heights vary from 30 inches to 36 inches for base cabinets and 30 inches to 42 inches for upper cabinets. However, you can customize these dimensions to suit your space and preferences.

- Optimizing Space: Utilize corner space efficiently with corner cabinets or shelves. Consider adding a pantry cabinet for large items.

Tools and Materials

Building cabinets requires a range of tools and materials.

- Tools: Essential tools include a tape measure, level, saw (circular or miter), drill, screwdriver, router, clamps, and safety gear like gloves and eye protection.

- Materials: The primary materials are wood (plywood, MDF, or solid wood), cabinet doors, drawer slides, hinges, screws, glue, and paint or stain.

Creating a Budget

A detailed budget is crucial for managing your project costs effectively.

- Material Costs: Estimate the cost of wood, cabinet doors, hardware, and other materials based on your design and local prices.

- Labor Costs: If you’re hiring professionals for specific tasks like cabinet door installation, include their labor costs in your budget.

- Contingency: Allocate a percentage (around 10-20%) for unexpected expenses or material price fluctuations.

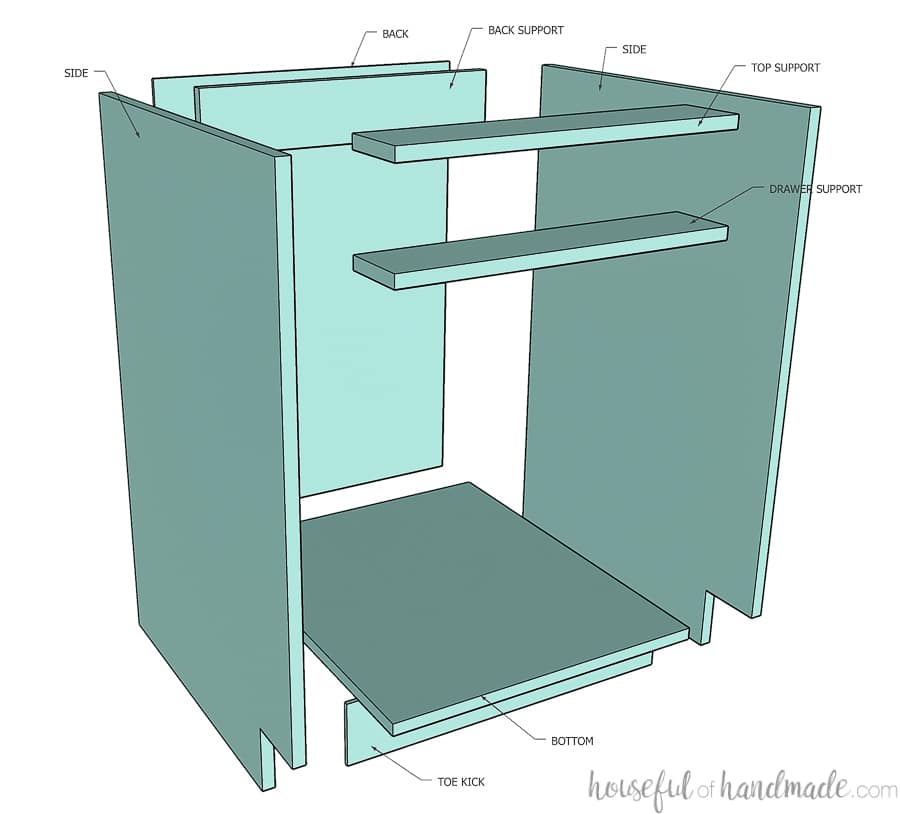

Building the Cabinet Structure

The foundation of your built-in cabinet project lies in the sturdy construction of its frame. This section delves into the techniques for cutting, assembling, and securing the cabinet frames, ensuring they provide a solid base for your shelves, drawers, and doors.

Cutting and Assembling the Cabinet Frames

Cutting and assembling the cabinet frames is a crucial step in building your cabinet. This involves precision cuts and strong joints to ensure the frame is sturdy and can withstand the weight of the cabinet contents.

The most common method for cutting wood for cabinet frames is using a table saw. This allows for precise cuts, ensuring the frame pieces fit together perfectly. A miter saw can also be used for cutting angles, which is essential for creating mitered joints. For intricate cuts, a jigsaw or band saw can be used.

Once the wood is cut, it needs to be assembled into a frame. There are several methods for joining wood together, but the most common for cabinet frames are:

- Pocket holes: This method involves drilling angled holes into the ends of the wood pieces and using screws to join them together. Pocket holes are strong and relatively easy to create.

- Dowel joints: This method involves drilling holes in the ends of the wood pieces and inserting dowels to connect them. Dowel joints are strong and provide a clean, finished look.

- Mortise and tenon joints: This method involves cutting a rectangular hole (mortise) in one piece of wood and a corresponding tongue (tenon) on the other piece. Mortise and tenon joints are very strong and provide a classic look.

The choice of joinery method depends on the complexity of the project, the desired strength, and the aesthetic look you are aiming for.

Cabinet Door and Drawer Front Construction

Once the cabinet frame is assembled, you can move on to creating the doors and drawer fronts. These are the visible elements of the cabinet, so it’s important to choose materials and construction techniques that match your design aesthetic and meet the required functionality.

- Materials: Common materials for cabinet doors and drawer fronts include plywood, MDF, solid wood, and glass. Plywood and MDF are affordable and versatile, while solid wood offers a more luxurious look. Glass can add a modern touch and allow for visibility into the cabinet.

- Construction Techniques: Several construction techniques can be used for cabinet doors and drawer fronts, including:

- Frame and panel: This traditional method involves constructing a frame and inserting a panel in the center. This technique offers a classic look and allows for different panel designs.

- Slab construction: This method uses a single piece of material for the door or drawer front. It’s simple and cost-effective, but may not be as strong as a frame and panel construction.

- Raised panel: This technique involves creating a raised panel on the surface of the door or drawer front. It offers a more decorative look and can add depth to the design.

Installing Hinges, Drawer Slides, and Other Hardware

After the doors and drawer fronts are built, it’s time to install the hardware. This includes hinges, drawer slides, knobs, and pulls.

- Hinges: Hinges connect the cabinet doors to the frame. There are various types of hinges available, including:

- Butt hinges: These are the most common type of hinge and are used for standard doors.

- Overlay hinges: These hinges are used when the door covers the frame.

- Inset hinges: These hinges are used when the door sits inside the frame.

- Drawer Slides: Drawer slides allow the drawers to move smoothly and easily. There are several types of drawer slides available, including:

- Side-mounted slides: These are the most common type of drawer slide and are mounted to the sides of the drawer.

- Under-mount slides: These slides are mounted to the bottom of the drawer and provide a cleaner look.

- Full-extension slides: These slides allow the drawer to extend fully, providing easy access to the contents.

- Knobs and Pulls: Knobs and pulls are used to open and close doors and drawers. They come in a wide variety of styles and materials to match any design aesthetic.

When installing hardware, it’s essential to use the correct tools and techniques to ensure a secure and smooth installation. Refer to the manufacturer’s instructions for specific installation guidelines.

Finishing and Installing Your Cabinets: Diy Built In Cabinet Plans

With the cabinet structure complete, it’s time to give your built-in cabinets the finishing touch. This involves selecting a finish that complements your room’s style, preparing the cabinet surfaces, and then applying the chosen finish. Finally, you’ll install the cabinets, ensuring proper alignment and support.

Finishing Options for Built-In Cabinets

The finishing options for your built-in cabinets can greatly impact their overall appearance and durability. Here are some popular choices:

- Paint: Paint offers a versatile and customizable finish, available in a wide range of colors and sheens. It’s a good choice for achieving a modern or contemporary look and can easily cover imperfections.

- Stain: Stain enhances the natural grain of the wood, allowing its beauty to shine through. It’s a popular choice for creating a rustic or traditional feel.

- Veneer: Veneer is a thin layer of wood that is glued to a less expensive substrate. It offers the appearance of a more expensive wood species and can be stained or painted to achieve the desired look.

Preparing Cabinet Surfaces for Finishing

Proper preparation is crucial for a successful finish. Follow these steps to ensure a smooth and even surface:

- Sanding: Sand the cabinet surfaces with progressively finer grits of sandpaper to remove any rough edges, imperfections, and dust particles.

- Cleaning: After sanding, thoroughly clean the surfaces with a tack cloth or a damp cloth to remove dust and debris.

- Priming: Apply a primer to the surfaces, which helps the finish adhere better and creates a uniform base.

Applying the Chosen Finish

Once the surfaces are prepared, you can apply the chosen finish. Follow these general guidelines:

- Paint: Apply paint in thin, even coats, allowing each coat to dry completely before applying the next.

- Stain: Apply stain according to the manufacturer’s instructions. Use a brush or cloth to evenly distribute the stain.

- Veneer: Apply a finish that is compatible with the veneer, such as polyurethane or varnish.

Installing the Cabinets, Diy built in cabinet plans

With the finishing complete, it’s time to install the cabinets in their designated locations.

- Leveling and Alignment: Use a level to ensure that the cabinets are installed level and plumb. Use shims as needed to adjust the position.

- Securing the Cabinets: Secure the cabinets to the walls using screws or other appropriate fasteners.

- Support: Ensure that the cabinets are adequately supported, especially if they are large or heavy.

Integrating Cabinets with Surrounding Walls and Trim

Seamlessly integrating the cabinets with the surrounding walls and trim enhances their appearance and creates a cohesive look.

- Matching Trim: Use trim that matches the cabinets’ finish to create a unified look.

- Cove Molding: Consider using cove molding to soften the transition between the cabinets and the walls.

- Crown Molding: Crown molding can add elegance and sophistication to the overall design.

Diy built in cabinet plans – DIY built-in cabinet plans are a great way to maximize space and add a custom touch to your kitchen. If you’re going for a modern look, consider pairing your cabinets with black stainless steel appliances with white shaker cabinets.

The contrast between the sleek black appliances and the clean white cabinets creates a striking and sophisticated aesthetic. With some planning and effort, you can build beautiful and functional cabinets that perfectly complement your chosen style.

DIY built-in cabinet plans can be a great way to maximize space and add a touch of custom design to your kitchen. If you’re looking for a modern and sleek aesthetic, consider pairing your cabinets with black stainless steel appliances and white cabinets.

This combination creates a striking contrast that’s both stylish and timeless. When planning your DIY built-in cabinets, remember to factor in the dimensions of your appliances to ensure a perfect fit.